Application Field

There are three 5T explosion-proof single-girder cranes in the customer's factory, and it is required to be able to solve the alarm of personnel intrusion in the hook area during the operation process and the obstacle identification during the crane walking process, so as to ensure the safety of personnel and equipment during the construction process.

Technical Difficulties

1. Low temperature and explosion-proof use environment: the winter temperature in the area where the equipment is used is -20°C, and the site requires handling in accordance with explosion-proof specifications.

2. Flow area monitoring: It is required to monitor whether there is any intrusion in the lower area of the hook during the walking operation.

3. AI recognition of overlooking angle: the on-site camera is installed on the driving trolley, and the capture angle is perpendicular to the ground, so the recognition is difficult.

4. The radar signal must respond quickly, and at the same time, it must also solve the problem of false alarms

Technical Solution

1. According to the customer's use environment, select suitable low-temperature and explosion-proof components.

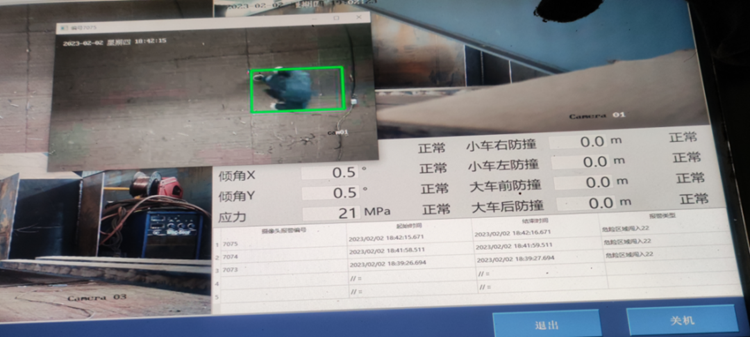

2. Traditional AI recognition combined with target detection technology, for the video image in the monitoring area, completes the preprocessing task of the video image through steps such as background modeling, grayscale transformation, smoothing filter, image enhancement, and edge detection; according to the principle of binocular stereo imaging , through the video image target detection results of adjacent cameras, complete the target stereo matching to obtain the target disparity map; judge whether the intruder has crossed the boundary to determine whether the event should be alerted.

Traditional personnel intrusion cameras capture personnel faces at a certain angle to identify them. The micro-special on-site camera is installed on a trolley, and the capture angle is perpendicular to the ground, which brings great difficulty to capture. Weite technical engineers braved the severe cold weather of minus 20°C, increased the amount of on-site material collection, and solved the identification of people from the overlooking angle through algorithm optimization and continuous on-site testing, finally meeting the customer's requirements.

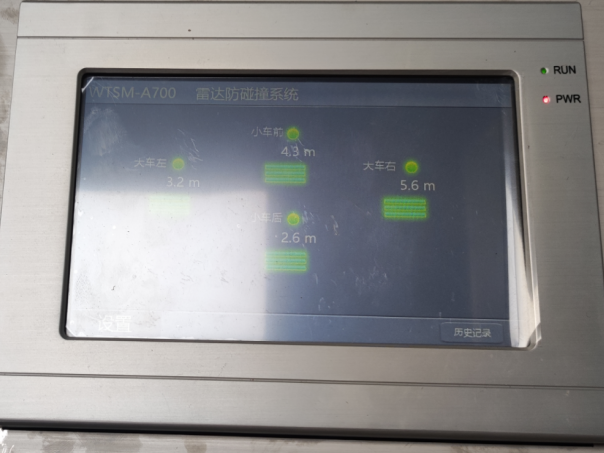

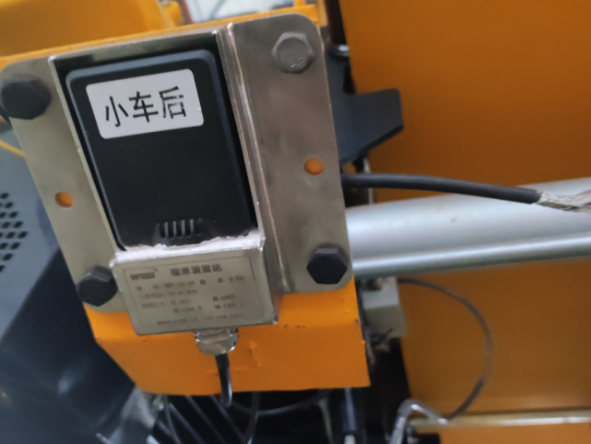

3. The anti-collision radar system monitors the bottom of the hook in real time. When a dangerous target (such as a cargo rack or other stacked objects) appears, the radar system sends an alarm to the crane driver in advance, so that the driver can respond in time, and the radar output signal arrives at the same time. The crane control system automatically stops or decelerates according to the situation.

By adjusting the angle of the on-site radar sensor and optimizing the algorithm, the radar signal can meet the requirements of fast and accurate identification.

Product & Service

1. Weite products have been exported to Russia, and have long-term cooperation with nuclear power, CNOOC and other customers. The low-temperature and explosion-proof technical solutions are relatively mature, and product testing can be carried out before the products leave the factory to ensure that the quality of the manufactured products meets the requirements of the customer's use environment.

Through repeated on-site testing and algorithm adjustment, the on-site realization of the accurate identification and alarm of personnel intrusion in the mobile dangerous area under the hook walking operation process according to the customer's requirements.

Through the on-site testing and adjustment of the radar sensor emission angle by the on-site staff of Weite, it is provided to the software engineer, and the software algorithm is continuously adjusted, and the on-site program is updated no less than 10 times. Finally, the obstacle detection direction forms a "back" shape, and the center of the back word and the thought area do not recognize obstacles, only between the big and small mouths.

Feedback

The customer has organized on-site inspection, the video recognition is accurate and effective, the radar recognition is fast and correct, and all functions meet the technical requirements and pass the acceptance inspection. At the same time, the customer expressed appreciation for the professionalism of the team shown by the technical engineers of Weite Technology who overcame the cold environment and persisted in their work, and the back-end software personnel responded quickly and cooperated in a timely manner.

As an expert in lifting safety protection, Weite has always focused on the research of lifting operation management, accumulated rich field experience in various fields, and is committed to providing users with safer and more efficient customized solutions.